-

Product Classification

-

Ship electric heater Gas electric heater Molten salt electric heater Air duct electric heater Fluid electric heater Corrosive gas electric heater Electric dust removal heater VOC electric heater RTO high temperature electric heater Far infrared reactor electric heater Heat transfer oil skid electric heater Chemical special heater Oil storage tank electric heater Military electric heater High temperature electric heater UOP reforming electric heater Explosion-proof heater PTC Heating element

-

Self-limiting temperature heating cable Solar special electric heating cable Constant power electric heating cable Heating cable MI armored heating cable Anti-corrosion sampling heat tracing composite pipe Glass fiber heating belt Industry-specific electric heating cable Electric heating accessories Electric heat tracing control system Silicone rubber heating belt

-

Electric heating tube (tubular) Soil repair electric heater Water tank electric heater Single-head tube electric heater Mold electric heater Boiler electric heater Hot air heater Pipe heater Combined motor heater Air heater Central air conditioning auxiliary heater Solar auxiliary electric heater Circulating electric heater Blower electric heater Drying electromechanical heater Lubrication equipment electric heater Cryogenic equipment Air separation heating Tracked electric heater

Industry Classification -

-

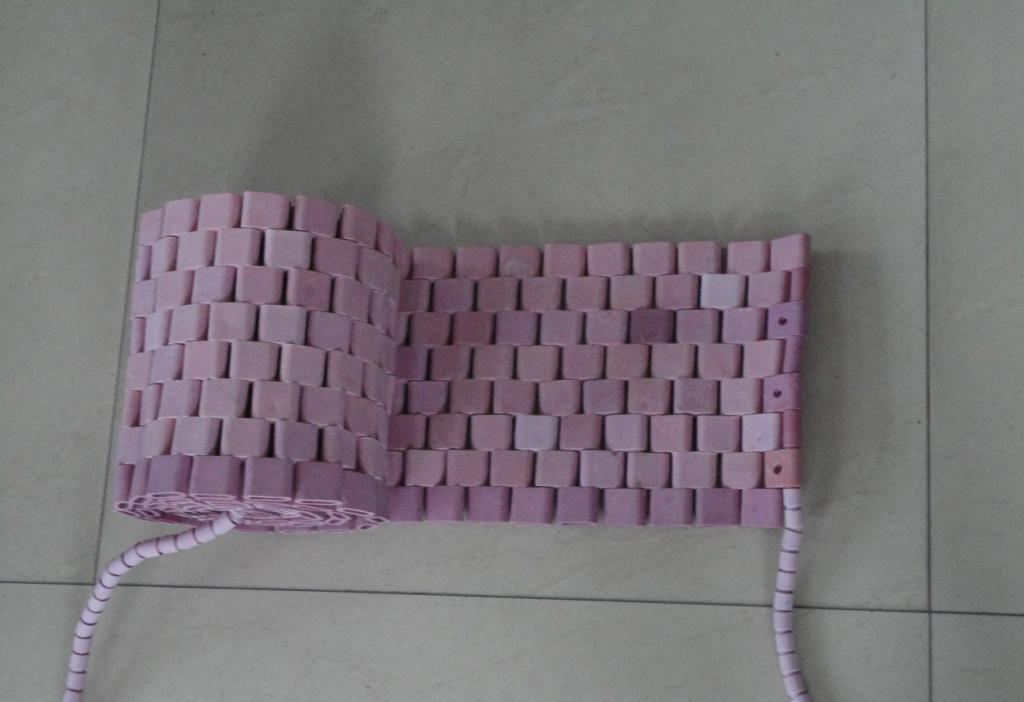

1. It has a winding property. For example, when heating a container or a pipe, it can be bent into a curved shape or a circular shape to heat the surface. For example, a large workpiece can be heated, and the part can be recovered and covered. The large-area workpiece can be in the form of a tile cover. In addition, it can be adapted to the heating of workpieces of various geometric shapes.

2, high operating temperature, fast heating, high thermal efficiency, no pollution, uniform heating and accurate, can achieve automatic control.

3. High mechanical strength, good thermal insulation performance, large contact surface with heated objects and long service life.

4, installation, maintenance is convenient, the use of low cost, even if the internal heating material is damaged, and the external ceramic device can still be reused. -

Rated voltage:220V、380V

Nominal power:Non-standard customization

Explosion-proof grade:ExdⅡBT4

Temperature control method:Automatic temperature control

Temperature control accuracy:±1℃

Explosion-proof grade:ExdⅡBT4

Whether flame retardant:Yes

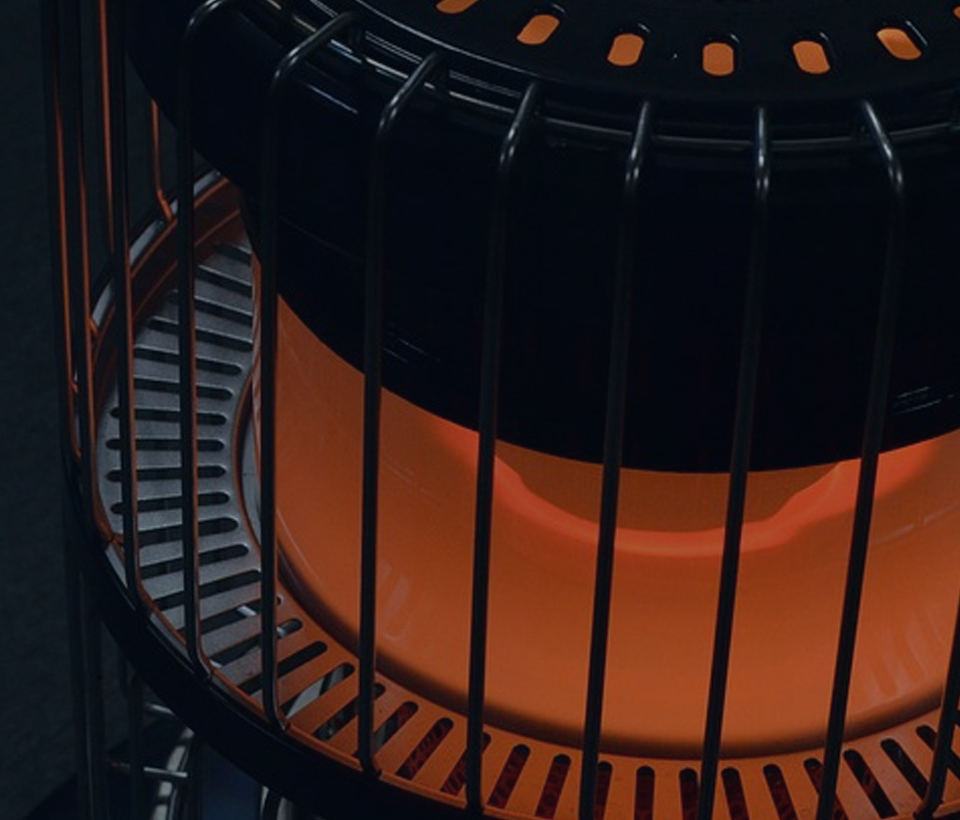

The preheating of various industrial equipment and large workpieces before welding and the stress relief after welding require local heat treatment. In order to improve the quality of the workpiece and strengthen the regional toughness. At present, in large workpieces or in the field, equipment maintenance is carried out by traditional, inefficient, high-energy high-frequency heating, flame heating or a large investment in the traditional method of manufacturing super heating furnaces for heat treatment. In addition, the old methods are used in the drying and high temperature heating of metal containers. Such as 1 steam pipe heating and water-oil partition indirect conduction heating method, (but not meeting some high-temperature heating requirements, and the container is also cumbersome, labor-intensive materials, difficult to repair). 2 destroy the container, using the electric heating rod insert heating method (some materials are not allowed to contact with the heating body or the electric heating rod is damaged after the contaminant material, and can be carried out after the material is released during maintenance). 3The electric porcelain wire is connected in series with the ordinary porcelain tube, and the external heating method is wound (the porcelain tube is in line contact with the container, the contact surface is small, the heat efficiency is low, and the ordinary porcelain piece is fragile and unsafe).

The crawler heater replaces the above-mentioned traditional backward method and is an ideal product for local heating, field heating, and external heating.

Follow us

Follow us